Cold Heading Design Guide Manufacturers Factory Suppliers From China If needed welcome to make contact with us by our web page or phone consultation we will be delighted to serve you. Diameter 125500 Length6 Max.

Cold Forming Overview And Reference Guide The Federal Group Usa

In cold-heading the initial design process is important because the process revolves around the proper tooling to.

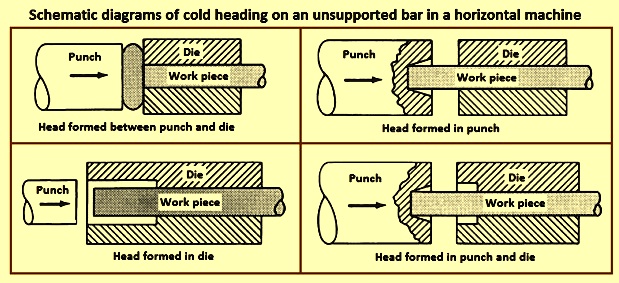

. While we manufacture fasteners for a variety of. The length-to-diameter ratio that can be headed without buckling is increased by use of sliding tools that support the part during heading. Most are cold formable.

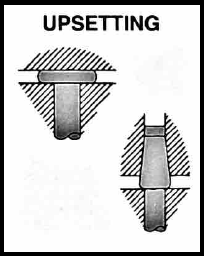

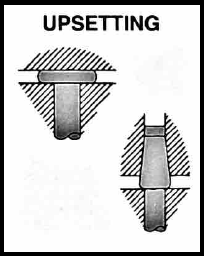

Can be forward backward or a combination of both. Heading Basics Introduction to Cold Heading Cold heading is a cold forming process that essentially involves applying force with a punch to the end of a metal blank contained in a die. Cold Headed Fasteners Made to Your Specifications In our domestic manufacturing plant near Cleveland Ohio we produce.

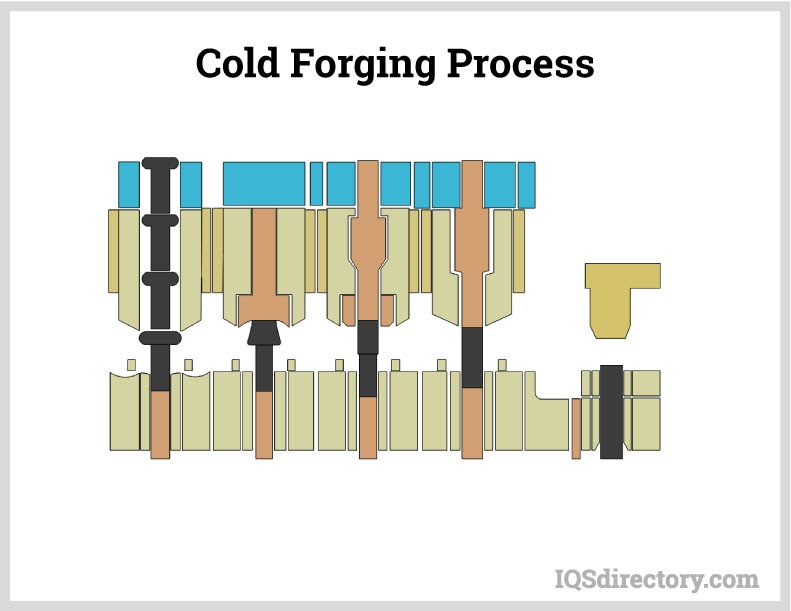

A universal designator system for Cold-Formed Steel Framing CFSF members has been used throughout the Guide. Cold heading is typically a high-speed process where a blank is progressively moved through a multi-station machine. Using our cold heading engineering expertise and unique low-volume cold heading process we were able to design a two-step specialty cold heading and secondary CNC machining process.

24 mm National 245 FC 5 Die. Introduction to Cold Heading Cold heading is a cold forming process that essentially involves applying force with a punch to the end of a metal blank contained in a die. Return to Table of Contents array markup 1.

Make one of the forced extrusion type and one of the open type. Make sketches with typical dimensions showing forward extrusion. Cold Header Tooling Design.

In cold-heading the initial design process is important because the process revolves around the proper tooling to stay within your tolerances. At Bossard an Applications Specialist works with the customers engineering department to select an acceptable replacement material for cold heading. Titanium and its alloys.

This article discusses various cold heading process parameters such. 54mil 16ga 68mil 14ga and 97mil 12ga products are. Advantages To Cold Forming.

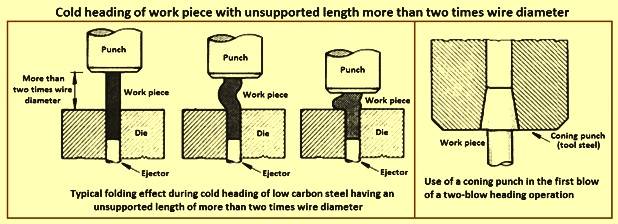

Cold heading or cold forming is the process of manufacturing parts at high speeds by changing the shape of a length of an unheated coiled wire that has been inserted into a die. Length of the part during the heading process. 3 33mil 20ga and 43mil 18ga framing products are produced with 33ksi steel.

Pure Ti and alloys with high ductility yes but alloys like 6-4. Metal forced through die by high fluid pressure. Platinum palladium tantalum and their alloys.

Exceed the design-stress calculationsIn additionthe much greater strength-to-weight ratio of forgings facil-itates the design of lighter-weight parts with corre-sponding cost savingsand. The design thickness to listed corner radius. The site of the cold chambers should be decided o nce the sizes are known but as a general rule they should be in the shade of direct sunlight.

Make a sketch with typical. Cold Heading Design Guide. Used for high-strength brittle and refractory alloys.

These include headers transfer headers bolt makers nut formers and parts formers. Avoid undercut diameters in products to be cold forged. AISI Cold-Formed Steel Framing Design Guide Second Edition Page ii.

Cold heading design guide Figure 3-24 Minimize diameter ratios. Cold heading can result in material cost savings that exceed 50 by reducing the amount of scrap that is produced by screw machining.

Cold Forming Overview And Reference Guide The Federal Group Usa

Cold Heading Quality Steels And Cold Heading Process Ispatguru

Cold Forming Overview And Reference Guide The Federal Group Usa

Cold Forging What Is It Benefits Process Hot Vs Cold Types Considerations

What Is Cold Heading Grandeur Fasteners Inc

What Is Cold Heading Grandeur Fasteners Inc

Cold Forming Overview And Reference Guide The Federal Group Usa

Cold Heading Quality Steels And Cold Heading Process Ispatguru

0 comments

Post a Comment